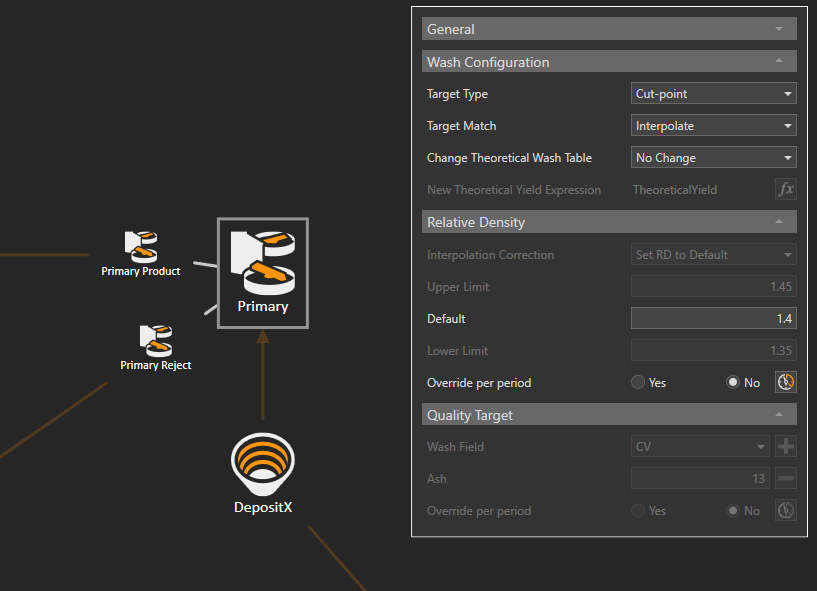

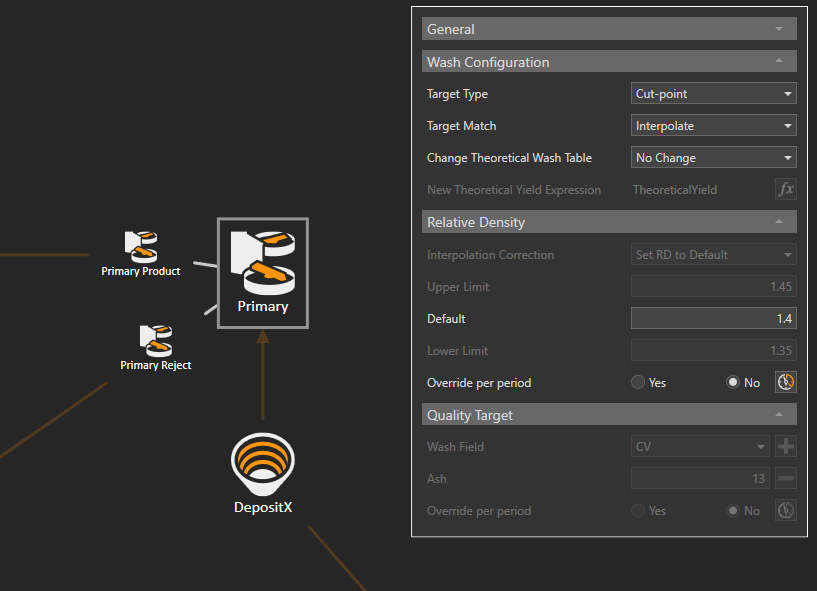

To visualise a wash plant node in the Material flow node menu the Wash Plant must be first configured and enabled.

A wash plant is a specialised process node that has two sub-processes, wash plant product and wash plant reject.

The feed to the wash plant node is processed by PO using the feed material wash table data. The PO can target qualities or cut-points, or adjust these to meet the overall material flow benefit settings. The plant yield will be driven by how the targets are met by PO and any yield adjustments.

When targeting qualities, the wash curve cut-points can be set to use the nearest wash table values or interpolated. When relative density (RD) interpolation is used, there are a number of options to control how to handle interpolated values.

The theoretical yield of the wash plant can be adjusted based on the qualities at the cut-point used by PO. When targeting cut-points, the yield can be based on average float qualities.

Assumptions

| Field | Description |

|---|---|

| Name | The name of the wash plant node. |

| Rate | The rate at which the plant processes input material in mass/hour. |

| Override per Period (General) | Option to override the wash plant Rate on a period basis. |

| Objective |

The objective rule the PO will attempt to satisfy. |

| Target Type |

The target type used by PO. Quantity: use one or more wash qualities for the PO target. If multiple targets are used, PO will use the lowest cut-point to meet the target. See Wash Field. Quality targets can be overridden on a period basis. Cut-point: uses the relative density as entered in the Relative Density > Default field as the PO target, or use override period values. Optimised Cut-point: allow PO to set the cut-point to meet overall material flow benefits. |

| Target Match |

The method PO will use when attempting to optimise the Target Type. Nearest: the cut density where the absolute difference between the quality value at either bound and the target quality value is lowest. Interpolate: the exact cut-point required to meet the target is determined by using a cut-point above and below the target, then using a straight line average (assuming that all wash data is linearly related). |

| Change Theoretical Wash Table |

Used to adjust the theoretical wash curves to achieve a practical yield to account for any misplaced material, such as material that floats but should have sunk and vice versa. No Change: no adjustment is made for the misplaced material and the New Theoretical Yield Expression row will be disabled. Use Qualities at RD Cut-point: The quality of the misplaced material will be the qualities of the material that floats at the current RD, but would have sunk at the previous RD. The wash table is then adjusted accordingly to take into account the 'good' material that will sink. Use Float Qualities: the quality of the misplaced material will be the average qualities of all coal that floats at that particular RD. The wash table is then adjusted accordingly to take into account the 'good' material that will sink. |

| New Theoretical Yield Expression | The yield expression to use if enabled by the Change Theoretical Wash Table setting. |

| Interpolation Correction |

How to manage the cut-point returned by PO (the cut-point used in the wash table). No RD Connection: do not adjust the relative density value used to achieve the PO target. Clamp RD to Limit: use the nearest RD limit value (upper and lower) in the wash curve if the PO cut-point is outside these limits. Set RD to Default: use the supplied default vale if the PO cut-point is above or below the limit values. |

| Upper Limit | The upper RD limit to use in interpolation rules. |

| Default | The default RD to use in interpolation rules. |

| Lower Limit | The lower RD limit to use in interpolation rules. |

| Override Per Period (Relative Density) | Override the RD limit values on a period basis. |

| Wash Field | The wash quality field for PO to target. Select the field from the list and click the green + icon to add a field. To remove a field, click the red - icon. |

|

Override Per Period (Quality Target) |

Override the wash quality targets on a period basis. |

The output of the wash plant is split into product and reject material that is represented by two sub-process nodes.

Each wash table quality of the wash plant product node can be adjusted with an expression that references the theoretical wash table qualities and the wash cut-point (as returned by PO). For example, when adjusting for practical wash values and overall plant efficiency factor.

To adjust product qualities

The wash plant reject is sent to a wash plant reject node. This node represents the wash plant feed minus the wash plant product material and can be renamed for reporting purposes.

The reject node can be used as a feed for secondary or two-stage washing. The reject node wash table is automatically adjusted to reflect the qualities and quantities removed by the primary wash plant as described in the next section.

When a secondary circuit is involved, the wash table needs to be recalculated to allow for material that was separated using a cut-point in the primary circuit. This is because the original wash table had yield and product quality data on a cumulative basis and is based on the original plant feed. However, the feed to the secondary circuit is the reject (sinks) stream of the primary circuit, and is, therefore different from the plant feed.

The following assumptions are used when arriving at the wash table for the secondary circuit.